Read more

Come with us to the production premises of the FENIX company, where the products of the ECOFLOOR series are manufactured under the hands of experienced operators.

We’ve prepared a new chapter "The most common causes of failures" for you, where we will gradually add illustrative examples of the mistakes, that can occur during the installation of our products. You can find the chapter in the Support section.

The unprofessionally performed repair of heating cables results, unnecessarily, in significantly higher damage.

A very common mistake is the damaging or incorrectly placement of heating cable connectors.

Selected Fenix products were tested by the Electrotechnical Testing Institute in Prague-Trója. The aim was to measure the electromagnetic fields of the products according to the valid technical standards. The results show that all of the measured values are well below acceptable limits.

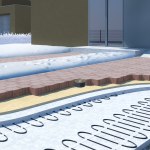

Heating mats are placed directly under floor tiling, in a thin layer of flexible sealant. They are easy to install and are highly economical to operate in connection with suitable temperature regulation. They are suitable for use as main heating systems as well as systems providing floor heating for added comfort.

We offer special mats 300-400 W/m² for outdoor applications in which the cable isn’t fixed to material, but is connected by fastening strips. After placement in sand the cable is thus better surrounded by backfill.

They are intended to be used under laminate and wooden floating floors installed in what are classified as humid areas – e.g. in bathrooms. They are a variant of ECOFILM heating foils for applications where ECOFILM cannot be used.

Heated rubber mat for the protection of entrance clean-off zones in shops, shopping centres and other areas with foot traffic against snow and ice.